Advantages of cast iron

Durable, versatile, and reliable for industrial use

Cast iron has been a cornerstone in industrial manufacturing for centuries. Its unique properties, such as remarkable strength, effective heat retention, machinability, and resistance to corrosion, continue making it a preferred choice across diverse industries, including commercial vehicles, construction and heavy machinery.

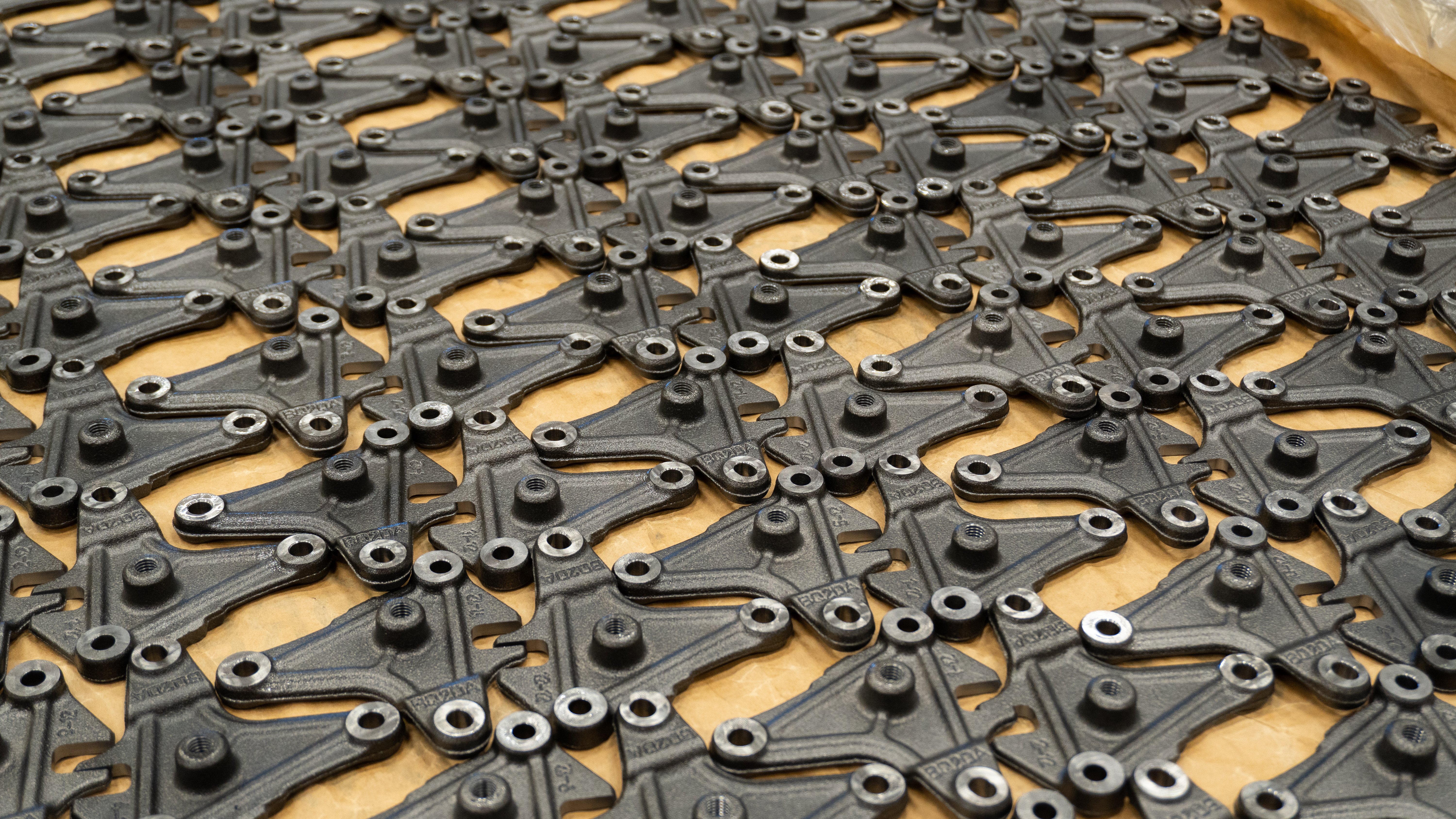

We are specialized in machining grey and ductile iron castings

As a specialized machine factory dedicated to machine grey and ductile iron castings we ensure precision components tailored to specific industrial requirements. Our many years of experience we guarantee consistent quality, reliability, and performance in critical industrial applications.

Key advantages of cast iron

Machinability and cost-effectiveness

Cast iron provides excellent machinability, allowing complex shapes. Transitioning from forged or fabricated components to cast iron often simplifies manufacturing, reducing both material costs and production times and allow more uniform geometrical shapes. Also, most often the CO2 footprint will be reduced due to less energy consumption and utilization of recycled material.

Exceptional durability and strength

Industrial cast iron components are widely known for their resilience under pressure, vibration, and demanding conditions. Cast iron’s robust structure significantly extends component life, reducing downtime and maintenance costs.

Superior heat retention and thermal stability

Due to excellent thermal conductivity and dimensional stability, cast iron is the ideal choice for heavy-duty applications involving high temperatures, vibrations and humid conditions. Industries frequently utilize cast iron in engine brackets, battery brackets, exhaust manifolds, hydraulic applications, gear housings, gear boxes, water pump housings, where consistent heat distribution is essential.

Corrosion resistance

When appropriately coated or surface-treated, cast iron resists rust and corrosion even in harsh environments. Protective surface treatment enhance its lifespan, reducing the frequency and cost of maintenance. Furthermore, cast iron is superior in corrosion resistance over steel, as the surface will hamper deep corrosion once the surface has corroded.

Industrial applications of cast iron

Thanks to its distinct advantages, cast iron serves crucial roles in several industries:

-

Commercial and passenger vehicles:

Cast iron are extensively used in the automotive sector for components such as engine blocks, brake discs, crankshafts, transmissions, engine brackets, battery brackets, mud guard brackets, cabin brackets, spring brackets, and various attachment brackets and structural components. -

Construction equipment:

Construction and earth-moving equipment demand robust components capable of handling shock loads and abrasive environments. Machined ductile cast iron delivers the strength and reliability needed for gear housings, engine parts, and hydraulic systems in contractor machinery. -

Material handling:

Forklifts, cranes, and conveyor systems require components that combine strength with dimensional accuracy. The rigidity and wear resistance of cast iron make it ideal for these applications, and the combination of casting design flexibility and our machining precision ensures optimal function and performance. -

Marine:

Marine engines and propulsion systems operate under harsh conditions, including saltwater exposure and high mechanical stress. Cast iron’s inherent stability and resistance to thermal stress make it a trusted material for marine components, especially when surface-treated for corrosion protection. -

Agricultural:

Agricultural machinery operates in challenging conditions, from heavy soil to variable weather. Cast iron parts provide durability and resistance to wear, supporting engines, transmissions, and structural components that keep farming equipment running efficiently season after season.

Maximizing cast iron’s benefits

To fully leverage cast iron’s strengths:

- Choose the right type of cast iron, alloy, and grade for the specific application.

- The high design flexibility of cast iron allows complex components to be produced in a single piece, reducing assembly work and increasing cost efficiency.

- Apply protective surface treatments or coatings for corrosion resistance.

Cast iron continues to play a vital role in industries due to its exceptional durability, versatility, thermal stability, and cost-efficiency. Selecting appropriate cast iron types, employing protective treatments, and optimizing designs allows industries to benefit from its reliability and proven performance, ensuring operational excellence across numerous industrial applications.

Ductile (nodular) cast iron vs. grey cast iron

Ductile iron, also called nodular cast iron or SG iron, offers improved flexibility and toughness compared to grey cast iron, making it ideal for high-stress parts such as engine and battery brackets, brake parts, cabin and suspension brackets, chassis brackets, connection rods, reaction rod brackets and various structural brackets. The ductility increases the mechanical properties especially with respect to elongation properties.

Cast iron vs. stainless steel

Cast iron provides several benefits compared to steel, such as excellent vibration dampening, cost advantages, and simpler production processes while steel deliver superior tensile strength suitable for high-performance applications.

Switching from steel fabrication or forging processes to cast iron casting streamlines manufacturing, reduces costs, and ensures consistent quality and performance. Choosing casting processes over traditional welding and forging can yield higher reliability and manufacturing efficiency.

Cast iron vs aluminium components

In many applications, utilization of cast iron mecanical properties will be an advantage over aluminium components. Due to higher strengt and for ductile iron also it’s ductility can reduce the size of the components. Further, the environment footprint will be reduced using cast iron as it is almost solely based on recycled materials.

Properties of cast iron

| Properties |

Grey cast iron | Ductile iron |

| Graphite form | Flake | Nodular |

| Strength | Moderate | High |

| Ductility | Low | High |

| Wear resistance | Good | Moderate |

| Machinability | Excellent | Moderate |

| Vibration damping | High | Moderate |

Contact

Manufacturers trust us to bring out the best in their most critical parts – and we are ready to earn your trust.

Joel Lundahl - Key Account Manager

Mobile: +46 791 433 268